About Us

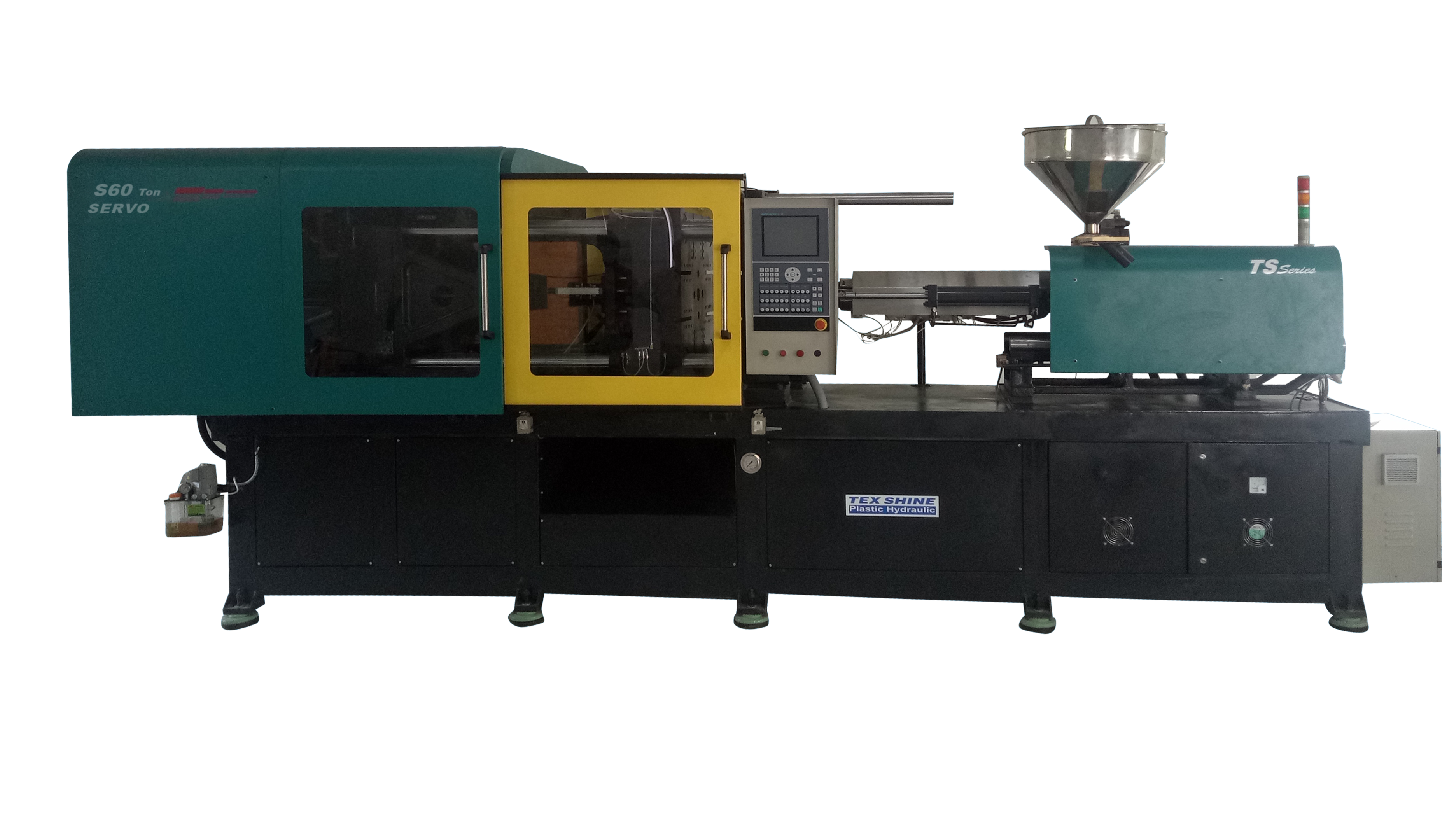

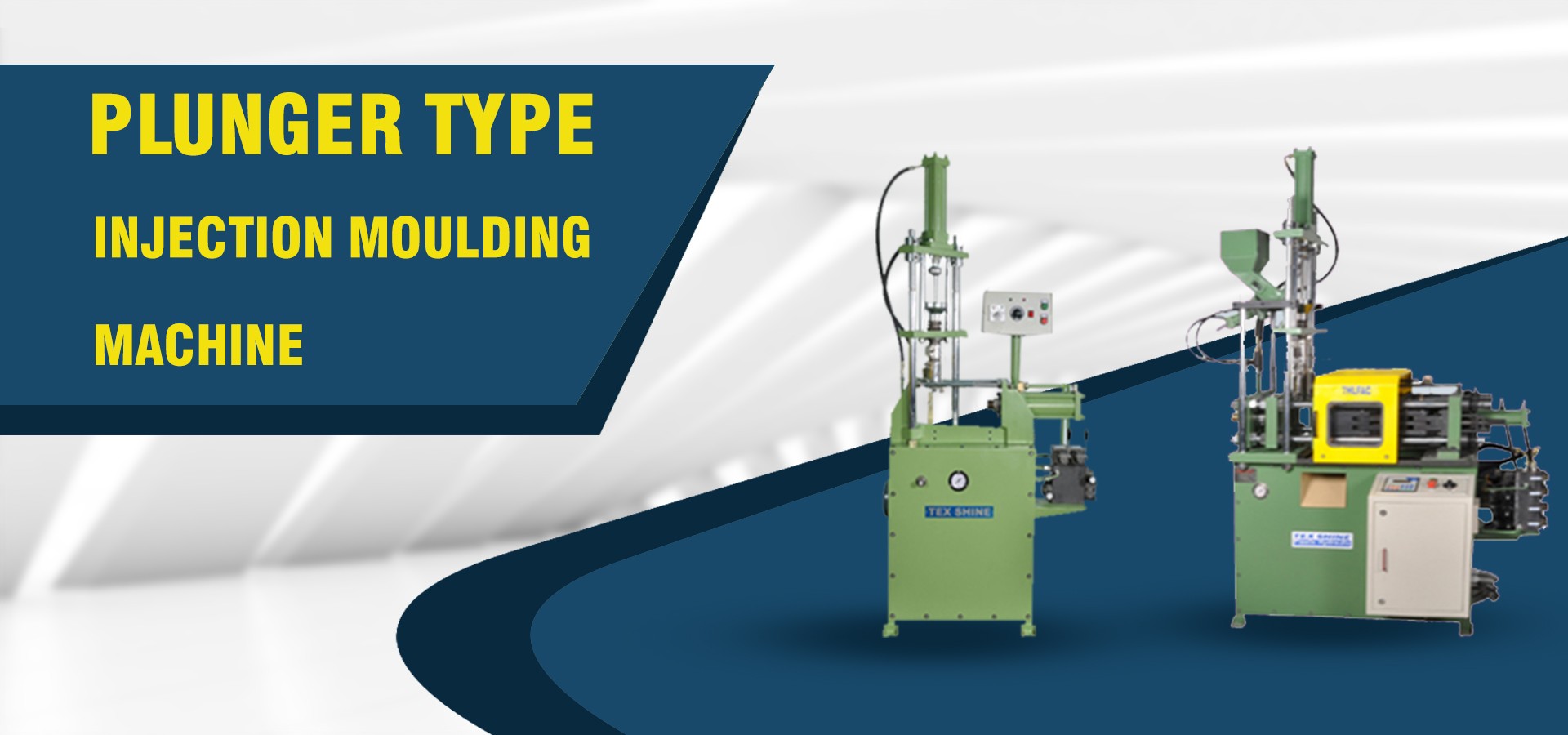

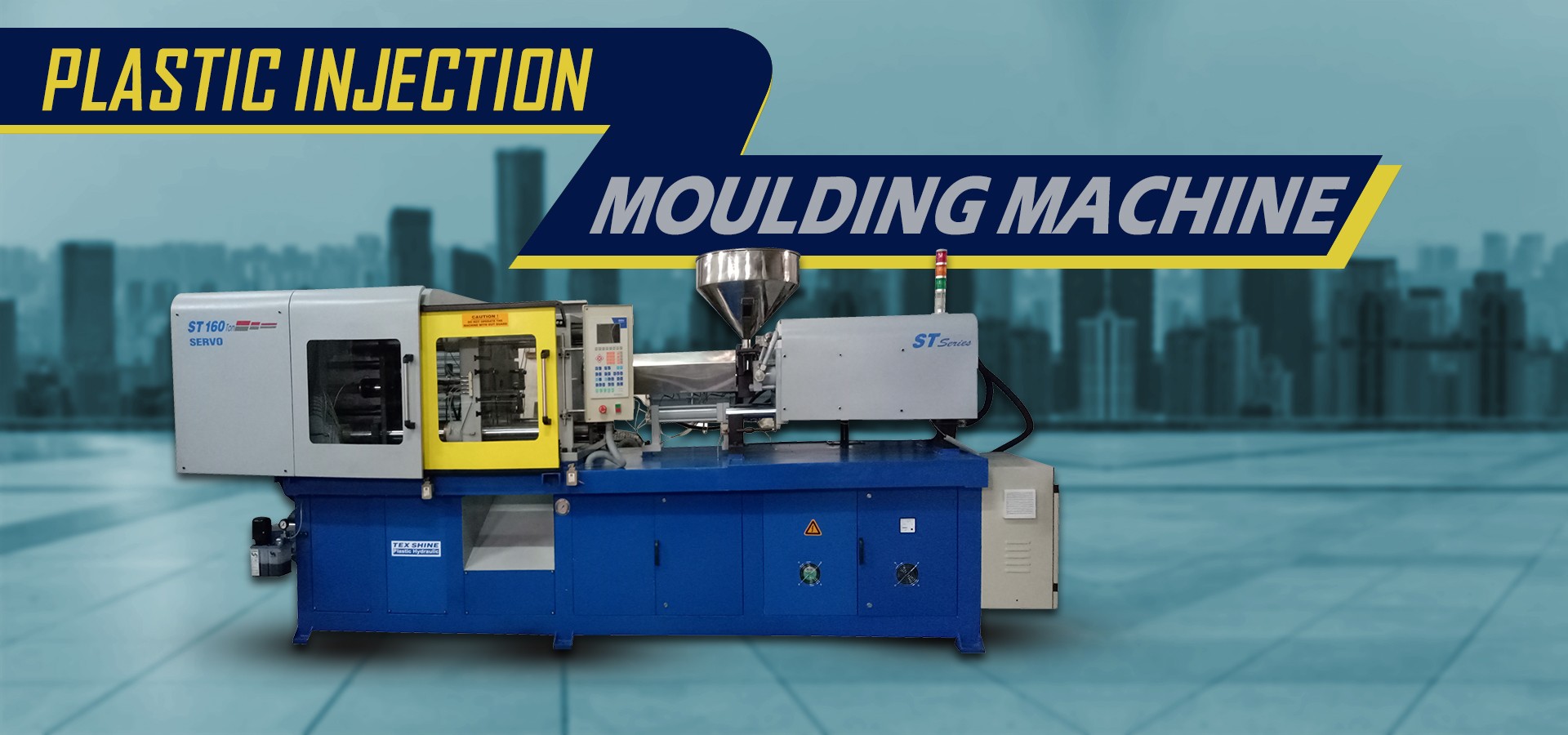

We have a reputation for excellent employee relations and have a highly experienced and motivated team whose single-minded aim is to meet and exceed our customer's product realization requirements. This company-wide culture provides a solid foundation from which to develop the customer relationships and quality of service that make us successful. Our production services include injection molding, vertical molding, insert molding, vertical plunger

Learn More